1. Introduction to Weighing Scales (Overview and History in Uganda)

A weighing scale is a device used to measure weight or mass. These are also known as mass scales, weight scales, mass balances, massometers, and weight balances.

Weighing scales have been an essential part of human civilization for centuries. These devices, used to measure the weight or mass of objects, have evolved from simple mechanical tools to sophisticated digital systems. Their history dates back to ancient civilizations like Mesopotamia and Egypt, where balance scales were used for trade and commerce.

The earliest balance scales were simple beam balances, consisting of a horizontal bar suspended on a central pivot. Equal weights were placed on either side to measure objects. Over time, these scales became more sophisticated, incorporating counterweights and materials like brass and bronze for durability and accuracy.

As trade and industry grew, the need for more precise and efficient weighing devices increased. This led to the development of spring scales, which use the deformation of a spring to measure weight. By the 20th century, electronic and digital scales revolutionized the industry, offering unparalleled accuracy and user-friendly features.

Today, weighing scales are indispensable tools in sectors ranging from agriculture and healthcare to manufacturing and retail. They play a critical role in ensuring fair trade, maintaining quality standards, and optimizing operational efficiency.

Relevance in Modern Times

In Uganda, weighing scales are crucial for various industries, including agriculture, transportation, and retail. Farmers use them to measure produce, logistics companies rely on them for accurate cargo weights, and retailers ensure fair pricing based on weight. As technology advances, businesses are adopting more sophisticated weighing solutions, such as digital and wireless systems, to improve accuracy and streamline operations.

2. Types of Weighing Scales

Weighing scales come in various types, each designed for specific applications. Understanding the different types helps in selecting the right scale for a particular need. Below are the most common types of weighing scales:

Mechanical Weighing Scales

Mechanical scales operate without the need for electricity. They rely on springs, levers, or counterweights to measure weight. These scales are simple, durable, and widely used in environments where digital solutions may not be feasible.

- Spring Scales: Measure weight based on the deformation of a spring. These are common in markets for weighing fruits and vegetables.

- Balance Scales: Consist of two plates balanced against each other. Often used in laboratories for precise measurements.

- Dial Scales: Feature a circular dial that shows weight measurements. These are popular for personal use, such as bathroom scales.

Digital Weighing Scales

Digital scales use electronic sensors to measure weight and display the results on an LCD screen. They are highly accurate and come with additional features like data storage and connectivity.

- Digital Kitchen Scales: Designed for precise measurement of ingredients, essential for baking and cooking.

- Digital Bathroom Scales: Used to monitor body weight, often equipped with additional features like BMI calculation.

- Digital Pocket Scales: Compact and portable, ideal for weighing small items like jewelry.

Industrial Weighing Scales

Industrial scales are built for heavy-duty applications, offering high capacity and durability. These scales are used in manufacturing, logistics, and agriculture.

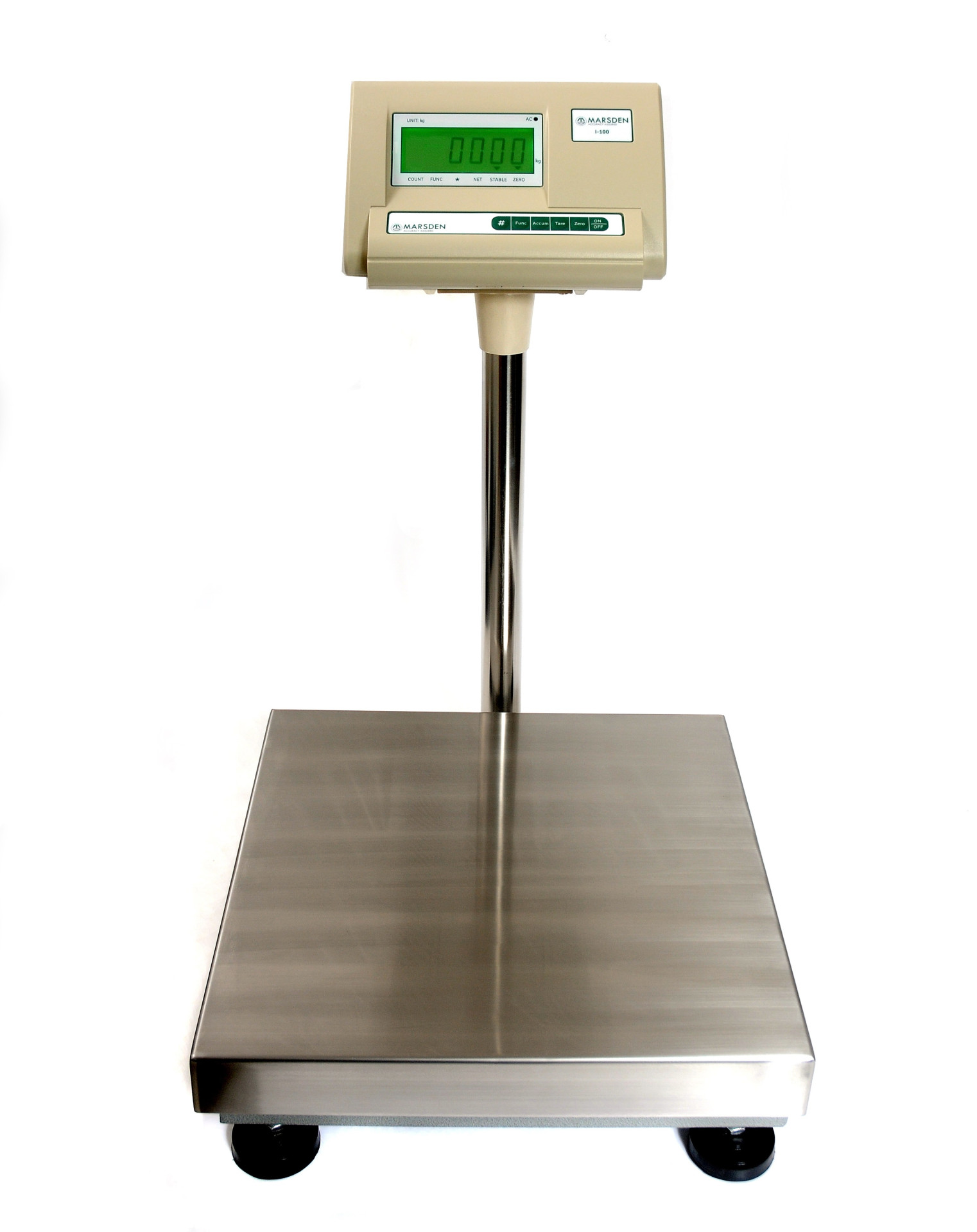

- Platform Scales: Feature a large surface for weighing heavy or bulky items. Common in warehouses and shipping industries.

- Floor Scales: Designed to measure the weight of pallets, crates, or machinery.

- Crane Scales: Suspended from a hook, used to weigh heavy loads in construction and logistics.

Specialized Weighing Scales

Certain scales are tailored for specific industries or tasks, offering unique features to meet specialized requirements.

- Animal Weighing Scales: Used in veterinary practices and farms to weigh livestock. These scales are built to handle movement and large weights.

- Moisture Analyzers: Combine weighing with moisture measurement, essential in industries like food processing.

- Counting Scales: Calculate the number of items based on their total weight, commonly used in manufacturing.

Weighbridges

Weighbridges are large scales designed to weigh vehicles and their contents. They are essential in industries like transportation, construction, and mining for determining the total load carried by trucks.

Advanced Weighing Solutions

Modern scales integrate advanced technologies like connectivity and automation:

- Wireless Scales: Allow remote monitoring and data collection.

- Smart Scales: Connect to mobile devices for tracking and analysis, popular in personal fitness and healthcare.

Choosing the Right Scale for Your Needs

The choice of scale depends on factors like capacity, precision, and application. For instance:

- A farmer in Uganda might need an animal weighing scale for livestock.

- A logistics company would benefit from a weighbridge or crane scale.

- Retail businesses often use digital counter scales for quick and accurate measurements.

3. Applications of Weighing Scales in Different Industries

Weighing scales play a vital role in countless industries by ensuring accuracy, efficiency, and fairness. Below is a breakdown of the applications of weighing scales in various sectors, with a focus on their relevance in Uganda.

Agriculture

In Uganda, agriculture is a key sector, and weighing scales are essential for measuring produce, livestock, and other agricultural outputs.

- Produce Weighing: Farmers use scales to measure crops like coffee, maize, and beans before sale or transportation.

- Animal Weighing: Livestock scales ensure accurate weight measurement for health monitoring and market transactions.

- Feed Measurement: Scales help measure animal feed to prevent overfeeding or underfeeding, optimizing productivity.

Retail and Commerce

Retail businesses depend on weighing scales to ensure fair pricing and customer satisfaction.

- Digital Counter Scales: Used in supermarkets and shops for weighing products like meat, fruits, and grains.

- Market Scales: Spring scales are common in open markets, offering a simple solution for weighing goods.

Industrial and Manufacturing

Weighing scales enhance efficiency and accuracy in industrial operations.

- Material Weighing: Platform and floor scales are used to measure raw materials like cement, metals, and plastics.

- Quality Control: Precision scales ensure that products meet weight specifications during production.

- Shipping and Logistics: Crane scales and weighbridges measure cargo weight to optimize transportation and avoid overloading.

Healthcare and Fitness

In healthcare, weighing scales provide critical data for patient care and fitness monitoring.

- Medical Scales: Used to monitor patient weight, crucial for diagnosing conditions like malnutrition or obesity.

- Infant Scales: Designed to weigh babies accurately, ensuring proper growth monitoring.

- Body Composition Scales: Track metrics like body fat percentage and muscle mass, popular in fitness centers.

Food and Beverage Industry

The food sector relies on weighing scales for portioning, quality control, and compliance with regulations.

- Ingredient Weighing: Digital kitchen scales ensure accurate measurements for recipes.

- Moisture Analyzers: Used to determine moisture content in grains, flour, and other food products.

- Packaging: Scales help measure and package food items precisely, reducing waste and maintaining consistency.

Transportation and Logistics

Weighbridges and axle load scales are indispensable for the transportation industry.

- Vehicle Weight Management: Ensures trucks comply with road weight limits, preventing accidents and road damage.

- Cargo Handling: Scales measure the weight of goods during loading and unloading.

Education and Research

Weighing scales are essential tools in laboratories and educational institutions.

- Scientific Research: Analytical balances measure minute quantities of chemicals and substances.

- Student Experiments: Schools use balance scales for teaching weight and mass concepts.

Mining and Construction

In mining and construction, scales measure raw materials like ore, sand, and gravel.

- Weighbridges: Monitor the weight of trucks carrying extracted materials.

- Portable Scales: Provide quick weight checks on-site.

Specialized Applications in Uganda

- Fish Processing: Scales measure fish weight for local and international markets.

- Coffee Grading: Precision scales help grade coffee beans, ensuring export quality standards.

- Sugar Industry: Scales measure sugarcane deliveries and processed sugar.

Impact of Weighing Scales on Efficiency and Fairness

Accurate weighing scales ensure transparency in transactions, prevent disputes, and improve productivity. They also help businesses comply with legal standards, such as Uganda’s Weights and Measures Act, which regulates the use of weighing equipment.

4. Benefits of Modern Weighing Scales

Modern weighing scales have revolutionized how businesses and individuals measure weight. They offer unparalleled accuracy, efficiency, and additional functionalities that enhance operations across various industries. Below are the key benefits of modern weighing scales, with examples relevant to Uganda.

1. Enhanced Accuracy

Modern scales, especially digital ones, provide precise measurements, ensuring reliability in various applications.

- Agriculture: Farmers can weigh produce accurately, ensuring they receive fair payment.

- Healthcare: Medical scales help monitor patient weight with precision, essential for proper diagnosis and treatment.

2. Ease of Use

Digital scales are user-friendly, with intuitive interfaces and automated features.

- Retail Scales: Provide quick readings, allowing faster transactions in supermarkets and markets.

- Kitchen Scales: Offer easy-to-read displays, making them convenient for measuring ingredients during cooking or baking.

3. Durability and Reliability

Modern weighing scales are built to withstand tough environments.

- Industrial Scales: Designed for heavy-duty applications, such as weighing construction materials or machinery.

- Portable Scales: Lightweight but robust, ideal for on-the-go use in agriculture or logistics.

4. Data Integration and Connectivity

Advanced digital scales come with features like data storage, USB ports, and wireless connectivity.

- Logistics: Businesses can integrate scales with software systems to track weights and manage inventories efficiently.

- Fitness: Smart scales sync with mobile apps, allowing users to monitor weight trends over time.

5. Multi-functionality

Many modern scales offer additional features beyond weight measurement.

- Body Composition Scales: Provide metrics like body fat percentage, muscle mass, and hydration levels.

- Counting Scales: Calculate the number of items based on total weight, streamlining inventory management in manufacturing.

6. Cost-Effectiveness

Though the initial investment may be higher, modern scales save money in the long run by reducing errors and improving efficiency.

- Retail Businesses: Avoid overcharging or undercharging customers due to inaccurate scales.

- Agricultural Use: Ensure accurate weighing of produce, reducing disputes and losses.

7. Compliance with Regulations

Modern weighing scales help businesses comply with legal standards.

- In Uganda, businesses must adhere to the Weights and Measures Act, which requires the use of certified and accurate weighing equipment. Digital scales simplify compliance by providing consistent results.

8. Environmental Benefits

Modern scales often use energy-efficient technologies, contributing to sustainability.

- Solar-Powered Scales: Useful in rural Uganda, where electricity access may be limited.

- Durability: Long-lasting devices reduce the need for frequent replacements, minimizing electronic waste.

9. Versatility Across Applications

Modern weighing scales cater to a wide range of needs.

- Agriculture: Measure both livestock and crops.

- Industry: Handle everything from small parts to heavy machinery.

- Healthcare: Serve both general patients and specialized needs like infant weighing.

10. Customization Options

Businesses can choose scales tailored to their specific requirements.

- Eagle Weighing Systems: Offers customized solutions like moisture analyzers for food processing or weighbridges for transportation.

Examples of Modern Scales in Uganda

- Digital Counter Scales: Widely used in Kampala’s retail outlets for weighing and pricing goods.

- Animal Weighing Scales: Beneficial for livestock farmers in areas like Masaka and Mbarara.

- Industrial Platform Scales: Used by factories in Jinja to weigh raw materials and finished products.

Modern weighing scales not only streamline operations but also boost productivity, profitability, and customer satisfaction.

5. Factors to Consider When Choosing a Weighing Scale

Selecting the right weighing scale is crucial for accuracy, efficiency, and suitability in its intended application. Below are key factors to consider when choosing a weighing scale, with examples tailored to the Ugandan market.

1. Purpose of Use

Understanding the primary purpose of the scale is the first step. Different applications require different types of scales.

- Retail: Digital counter scales are ideal for shops and supermarkets in Kampala.

- Agriculture: Platform scales are perfect for weighing farm produce like coffee, maize, and beans.

- Healthcare: Medical scales cater to patient weight monitoring, while infant scales focus on babies’ growth tracking.

2. Capacity

The scale’s capacity must match the weight of the items it will measure. Overloading can damage the scale or produce inaccurate readings.

- Low-Capacity Scales: Ideal for jewelry, laboratory, or kitchen use.

- High-Capacity Scales: Suitable for industrial applications like weighing construction materials or livestock.

3. Precision and Accuracy

Precision is critical, especially for industries requiring exact measurements.

- Precision Scales: Common in laboratories for chemical measurements.

- General Use Scales: Suitable for weighing goods in open markets or supermarkets.

4. Durability

Scales used in harsh environments should be durable and resistant to wear and tear.

- Agricultural Scales: Must withstand outdoor conditions, dirt, and heavy use.

- Industrial Scales: Should handle heavy loads and rough environments, like construction sites or factories.

5. Type of Scale

Choosing the right type depends on the intended use.

- Mechanical Scales: Suitable for basic needs, such as market use in rural areas.

- Digital Scales: Ideal for applications requiring precision and additional features like data storage.

- Weighbridges: Essential for transportation and logistics companies to weigh vehicles.

6. Ease of Use

User-friendly scales reduce the learning curve and improve efficiency.

- Digital Scales: Feature clear displays and simple controls, making them suitable for both novice and experienced users.

- Smart Scales: Offer automated readings and connectivity for seamless operation.

7. Calibration Needs

Regular calibration ensures the scale remains accurate.

- Manual Calibration: Required for mechanical scales, which might need regular adjustment.

- Automatic Calibration: Available in advanced digital scales, saving time and effort.

8. Portability

For businesses requiring mobility, portable scales are a practical choice.

- Portable Platform Scales: Useful for smallholder farmers weighing produce in remote areas.

- Digital Pocket Scales: Compact and easy to carry, ideal for mobile jewelers or vendors.

9. Connectivity Options

Modern scales often come with features like Bluetooth, Wi-Fi, or USB connectivity.

- Retail Businesses: Scales with connectivity can integrate with point-of-sale systems for streamlined operations.

- Industrial Use: Connectivity aids in automating inventory management.

10. Power Source

The availability of a power source influences the type of scale to choose.

- Solar-Powered Scales: Suitable for rural areas in Uganda with limited access to electricity.

- Battery-Powered Scales: Offer portability and convenience for mobile businesses.

11. Compliance with Regulations

Scales must meet legal standards to ensure fairness and accuracy.

- In Uganda, certified scales compliant with the Weights and Measures Act are mandatory for trade purposes.

12. Brand and Supplier

Choosing a trusted brand and supplier ensures quality and support.

- Eagle Weighing Systems: Offers a wide range of reliable weighing solutions, tailored to different industries in Uganda.

13. Cost and Budget

Balancing quality and affordability is essential when selecting a scale.

- Affordable Options: Mechanical or basic digital scales for small businesses.

- Premium Options: High-capacity industrial scales or advanced models with extra features.

Examples of Practical Choices in Uganda

- Farmers in Masaka: May opt for platform scales to weigh bulk produce.

- Retailers in Kampala: Benefit from digital counter scales for faster customer service.

- Logistics Companies: Use weighbridges to ensure legal and accurate cargo measurements.

Choosing the right scale ensures efficiency, reliability, and compliance with standards. By evaluating these factors, businesses and individuals can invest in a scale that meets their needs and supports their operations effectively.

6. Maintenance and Calibration of Weighing Scales

To ensure the accuracy, longevity, and optimal performance of weighing scales, regular maintenance and proper calibration are essential. Below is a guide to maintaining and calibrating weighing scales, focusing on applications in Uganda.

1. Importance of Regular Maintenance

Regular maintenance ensures that weighing scales continue to provide accurate and consistent results over time. Neglecting maintenance can lead to inaccurate readings, which could affect business operations and compliance with regulations.

2. Basic Maintenance Tips

a. Cleaning

- Daily Cleaning: Wipe down scales to remove dirt, dust, and residue that could interfere with performance.

- Use of Appropriate Cleaning Solutions: Avoid abrasive materials that may scratch the surface, especially for digital or sensitive scales.

b. Check Load Cells

- Inspect load cells regularly for damage or wear, as these are critical components that affect weight measurement.

- For industrial and agricultural scales, ensure load cells are not overloaded beyond their capacity.

c. Inspect Display and Controls

- Ensure digital displays are clear and functional. Repair or replace displays that malfunction.

- Check that all buttons and controls respond accurately without sticking or lagging.

d. Battery and Power Source

- Regularly inspect and replace batteries in battery-powered scales to avoid sudden shutdowns during operation.

- For solar-powered or mains-powered scales, ensure proper power supply management.

3. Calibration of Weighing Scales

Calibration is the process of adjusting a scale to ensure its readings are accurate. Below are steps to calibrate different types of scales:

a. Digital Scales

- Automatic Calibration: Most modern digital scales have built-in calibration functions. Follow the manufacturer’s instructions.

- Manual Calibration: Use known weights (standard calibration weights) to adjust scale accuracy if necessary.

b. Mechanical Scales

- Regular Recalibration: Mechanical scales may require frequent recalibration, especially in harsh environments.

- Zero Adjustment: Ensure the scale reads zero when no weight is placed on it.

c. Platform and Floor Scales

- Periodic Calibration: Industrial platform scales used in factories or construction sites must be calibrated periodically to maintain accuracy.

- Load Testing: Ensure the scale can handle varying loads without significant discrepancies.

4. Compliance with Legal Standards

In Uganda, scales used for commercial purposes must adhere to the Weights and Measures Act. This includes using certified and regularly calibrated scales for trade transactions.

- Certification: Work with accredited calibration centers like Eagle Weighing Systems to ensure your scale is certified for legal trade use.

5. Troubleshooting Common Issues

a. Inaccurate Readings

- Check for dirt or debris affecting load cells.

- Verify the scale’s calibration status and adjust if necessary.

b. Erratic Display or Functionality

- Inspect wiring and connections for any loose connections or physical damage.

- Replace malfunctioning components such as fuses, batteries, or control modules.

c. Overload Warnings

- Ensure that heavy items are not exceeding the scale’s rated capacity.

6. Maintenance Schedule

Establishing a regular maintenance schedule helps ensure scales remain accurate and reliable. Below is a basic guide:

- Daily: Clean scales and inspect basic functionality (e.g., zero readings and control buttons).

- Monthly: Conduct thorough inspections and calibration checks.

- Annually: Perform full maintenance, including load testing and component replacement, if necessary.

7. Professional Servicing

For industrial or high-capacity scales, periodic professional servicing is recommended to handle heavy wear and tear, especially for scales used in construction, manufacturing, or logistics.

8. Benefits of Proper Maintenance and Calibration

- Accuracy: Ensures fair transactions and prevents disputes.

- Efficiency: Maintains consistent performance, reducing downtime and operational disruptions.

- Compliance: Meets legal and regulatory requirements.

Examples in Uganda

- Farmers in rural Uganda benefit from regular calibration to avoid loss during sales of produce at markets.

- Retailers in urban areas like Kampala rely on well-maintained scales to ensure accurate pricing and customer trust.

Proper maintenance and calibration are essential to the longevity and accuracy of weighing scales. Regular checks and adherence to best practices ensure that businesses operate efficiently while maintaining compliance with industry standards.

7. Choosing the Right Weighing Scale Supplier in Uganda

Selecting the right supplier for weighing scales is crucial for obtaining quality products, reliable support, and after-sales service. Below are important considerations when choosing a weighing scale supplier in Uganda, along with insights into Eagle Weighing Systems as a trusted provider.

1. Quality and Certification

- Certified Products: Ensure that the supplier provides scales that meet Ugandan standards, such as the Weights and Measures Act.

- Durability and Accuracy: Reliable suppliers offer scales that are tested and certified for both precision and durability.

2. Range of Products

- Variety: Choose a supplier offering a wide range of scales—ranging from basic digital scales to high-capacity industrial weighbridges.

- Customization: Suppliers like Eagle Weighing Systems can customize solutions based on specific industry needs, such as agriculture, logistics, healthcare, or retail.

3. After-Sales Support and Maintenance Services

- Service and Repairs: A good supplier offers comprehensive after-sales services, including calibration, repairs, and maintenance.

- Training: Suppliers provide training on how to operate and maintain different types of scales, ensuring their clients get the most out of their investment.

4. Pricing and Value for Money

- Cost-Effective Solutions: Compare prices while considering quality and long-term performance.

- Warranty: Look for suppliers that provide warranties and guarantees on their products, ensuring customer satisfaction and trust.

5. Experience and Reputation

- Established Track Record: Suppliers with years of experience and positive customer reviews are more likely to offer reliable products and services.

- Local Expertise: A supplier familiar with local regulations and environmental conditions will be better equipped to provide tailored solutions for the Ugandan market.

6. Technology and Features

- Innovative Solutions: Suppliers offering advanced features like connectivity, data management, and smart functionalities are ideal for modern businesses.

- Eco-Friendly Options: Solar-powered and energy-efficient scales are increasingly popular in rural and urban Uganda.

7. Supply Chain and Accessibility

- Local Presence: Suppliers with strong local operations can provide faster service and better support.

- Delivery and Installation: Consider suppliers offering efficient delivery, installation, and setup services.

8. Testimonials and References

- Customer Feedback: Seek out references and case studies from previous customers to assess the supplier’s reliability and service quality.

- Partnerships: Suppliers like Eagle Weighing Systems have built partnerships with businesses across Uganda, providing tailored solutions that meet industry needs.

Why Choose Eagle Weighing Systems?

Eagle Weighing Systems has become a trusted supplier in Uganda by providing high-quality weighing solutions tailored to various industries. With a focus on customer satisfaction, they offer:

- Wide Range of Products: From precision scales to heavy-duty industrial scales.

- Local Support: Expert service technicians and calibration services across Uganda.

- Affordable Solutions: Competitive pricing without compromising on quality and durability.

- Compliance: Certified scales that meet Ugandan regulatory standards.

Examples of Eagle Weighing Systems’ Offerings

- 60T Weighbridges for logistics companies in Mbale.

- Digital Retail Scales used by supermarkets in Kampala.

- Agricultural Scales helping farmers in Mukono weigh crops accurately.

Choosing the right weighing scale supplier ensures that your business or personal needs are met with reliable, accurate, and cost-effective solutions. Suppliers like Eagle Weighing Systems stand out by providing quality products, excellent customer service, and tailored solutions to meet Uganda’s diverse weighing needs.

8. Future Trends in Weighing Scales for Uganda

As technology continues to evolve, the future of weighing scales in Uganda is set to become more advanced, efficient, and sustainable. Below are some key trends shaping the future of weighing solutions in Uganda, highlighting opportunities for businesses and industries.

1. Smart and IoT-Enabled Weighing Scales

- Integration with IoT: Smart weighing scales equipped with IoT (Internet of Things) capabilities are becoming increasingly popular. These scales can connect to networks, providing real-time data for inventory management, quality control, and operational efficiency.

- Applications: Retail stores, agricultural cooperatives, and logistics companies can benefit from connected scales to track and manage goods more effectively.

2. Enhanced Accuracy and Precision

- Advanced Sensors: Future scales will integrate advanced load sensors and weight measurement technology to offer even higher precision for various industries.

- Importance in Agriculture and Manufacturing: Enhanced accuracy is critical for industries like agriculture (e.g., weighing produce) and manufacturing (e.g., precision weighing of raw materials).

3. Sustainability and Eco-Friendly Designs

- Solar-Powered and Energy-Efficient Scales: With the increasing focus on sustainability, solar-powered and energy-efficient scales are becoming more common. These solutions are ideal for rural areas where access to electricity is limited.

- Waste Reduction: Scales designed to minimize waste, such as multi-use scales or biodegradable materials for components, will emerge as eco-conscious solutions.

4. Automation and Artificial Intelligence (AI)

- Automated Weighing Solutions: Future scales will leverage AI for automated decision-making and operational optimization.

- Predictive Maintenance: AI can be used to predict maintenance needs and reduce downtime, especially in industries requiring high throughput, like logistics and manufacturing.

5. Customization and Industry-Specific Solutions

- Tailored Solutions: Future trends indicate a rise in customized scales designed for specific industries like food processing, pharmaceuticals, and construction.

- Modular Designs: Scales that allow for modular configurations will cater to industries requiring flexibility in their weighing solutions.

6. Greater Connectivity and Data Analytics

- Data-Driven Insights: Businesses will increasingly rely on scales that provide detailed data analytics to optimize their operations.

- Cloud Integration: Cloud-connected scales will enable seamless data sharing and real-time insights into business processes, especially for logistics and e-commerce businesses in urban and rural Uganda.

7. Compliance and Regulatory Advancements

- Stricter Standards: As regulations around the use of weighing scales become more stringent, manufacturers and suppliers in Uganda will focus on developing solutions that meet evolving compliance requirements.

- Certification and Calibration Innovations: Future scales will incorporate advanced features to streamline certification and calibration processes, ensuring adherence to national standards.

8. Portability and Versatility

- Portable and Versatile Options: Scales designed for versatility will become more popular, especially for small businesses or mobile industries like food vendors, construction workers, or event organizers in Uganda.

9. Integration with Mobile and Web Applications

- Mobile-Connected Scales: Weighing scales will increasingly integrate with mobile apps and web platforms for easy access to data and monitoring.

- Custom Apps for Businesses: Scales will offer customized applications tailored to the needs of businesses for inventory tracking, reporting, and operational analysis.

10. Affordable and Accessible Solutions

- Lower-Cost Innovations: Future technologies will aim at providing cost-effective solutions without compromising performance, allowing small businesses and individuals in Uganda to access advanced weighing solutions.

Examples of Future Trends

- Agricultural cooperatives in northern Uganda can adopt solar-powered platform scales to improve efficiency in weighing crops for export markets.

- Logistics companies in Kampala will benefit from smart weighing systems with real-time data analytics for better supply chain management.

The future of weighing scales in Uganda is set to be shaped by advancements in technology, sustainability, and customized solutions. By integrating smart features, sustainability, and regulatory compliance, businesses and industries will be able to optimize their operations, improve accuracy, and ensure long-term growth.

9. How to Choose the Right Weighing Scale for Your Needs

Selecting the right weighing scale for your specific needs is crucial to ensure efficiency, accuracy, and compliance with industry standards. Below are key factors to consider when choosing a weighing scale for your business in Uganda.

1. Understand Your Specific Needs

Before choosing a weighing scale, it is important to determine the purpose and application. Common considerations include:

- Industry: Agriculture, retail, manufacturing, logistics, healthcare, etc.

- Weight Capacity: The scale’s ability to handle different loads (e.g., grams for jewelry or kilograms for agricultural produce).

- Accuracy Requirements: The need for precise measurements, especially in trade or manufacturing.

2. Types of Weighing Scales

a. Digital Scales

- Features: Offer high accuracy and are user-friendly with digital displays. Ideal for precision applications such as retail, pharmaceuticals, and food processing.

- Applications: Supermarkets, bakeries, pharmacies, and manufacturing sectors.

b. Mechanical Scales

- Features: Depend on springs and mechanical components, suitable for basic, non-digital weighing.

- Applications: Laboratories, schools, and industries requiring simple weighing.

c. Platform Scales

- Features: Ideal for heavy-duty use with a flat, large surface for weighing bulky items.

- Applications: Warehouses, manufacturing, and construction sites.

d. Weighbridges

- Features: Heavy-duty scales used for measuring vehicles and large quantities of goods.

- Applications: Logistics, mining, and agricultural exports.

3. Capacity and Precision

- Weight Capacity: Choose a scale that meets your capacity needs. For example, small businesses may require a 60kg scale, while large industrial operations may need 60-ton weighbridges.

- Accuracy: Ensure the scale meets your required level of precision—especially important in trade, legal metrology, and food industries.

4. Portability and Mobility

- Portable Scales: Essential for businesses with fluctuating work environments (e.g., fieldwork for agricultural cooperatives or event organizers).

- Fixed vs Portable: Consider where and how the scale will be used—fixed scales are ideal for permanent locations, whereas portable scales offer flexibility.

5. Environmental Factors

- Durability: Scales used outdoors or in harsh environments should be weatherproof and resistant to dust, water, and extreme temperatures.

- Power Supply: Scales may be powered by electricity, batteries, or solar energy, depending on location accessibility to power.

6. Certification and Legal Compliance

- Standards: Ensure the scale complies with Uganda’s legal standards under the Weights and Measures Act.

- Calibration: Consider suppliers like Eagle Weighing Systems who offer certified calibration services to ensure accurate readings for trade.

7. Cost vs. Value

- Initial Cost: While affordability is important, balance cost with quality and long-term value.

- Maintenance Costs: Consider ongoing maintenance and repair costs for high-capacity or complex scales.

8. Supplier Reputation and After-Sales Support

- Trusted Suppliers: Partner with suppliers who provide reliable support for installation, maintenance, and troubleshooting.

- Warranty and Service: Suppliers like Eagle Weighing Systems offer after-sales support and service contracts for long-term use and peace of mind.

9. Industry-Specific Features

- Specialized Scales: Certain industries require scales with specialized features—e.g., hygiene features for food processing or explosion-proof scales for chemical industries.

10. Reviews and Recommendations

- Customer Feedback: Read reviews and testimonials from other businesses in similar industries to ensure reliability and customer satisfaction.

Conclusion

Selecting the right weighing scale involves understanding your specific needs and finding a solution that balances accuracy, durability, functionality, and cost. Working with reputable suppliers like Eagle Weighing Systems ensures that your business operates efficiently and complies with legal standards.

10. Benefits of Using Advanced Weighing Scales in Uganda

Advanced weighing scales provide numerous benefits for businesses, industries, and individuals in Uganda. These technologies help improve accuracy, efficiency, and overall operations. Below are the key benefits of incorporating advanced weighing scales into various applications.

1. Increased Accuracy and Precision

- Accurate Measurements: Advanced weighing scales offer precise measurements, reducing errors in business operations like trade, manufacturing, and logistics.

- Impact: In industries such as agriculture, where precise measurements are critical for pricing and product quality, accurate scales ensure the right amount of produce is weighed and valued.

2. Time Efficiency and Faster Operations

- Speed: Digital and automated weighing scales significantly speed up the weighing process, leading to faster operations in retail, logistics, and manufacturing.

- Improved Productivity: Reducing the time spent on manual weighing allows businesses to handle a higher volume of transactions, thereby boosting productivity.

3. Enhanced Data Management and Reporting

- Data Collection: Advanced scales collect, store, and transmit data seamlessly, offering valuable insights into business performance.

- Integration with Software: Scales integrated with management systems provide real-time data for inventory management, helping businesses optimize their supply chains.

4. Cost-Effectiveness

- Reduced Errors: Accurate measurements help reduce losses due to over- or under-weighing, which can lead to financial savings.

- Energy Efficiency: Advanced scales, such as solar-powered models, offer cost savings on electricity, particularly in rural or off-grid locations.

5. Versatility and Customization

- Wide Range of Options: Modern scales come in various forms, including portable, bench-top, and industrial-grade models.

- Tailored Solutions: Suppliers like Eagle Weighing Systems provide customized solutions that meet specific industry needs—be it agricultural weighing, healthcare, or logistics.

6. Compliance with Legal and Regulatory Standards

- Regulatory Adherence: Scales that comply with Uganda’s Weights and Measures Act ensure that businesses operate legally and avoid penalties associated with inaccurate measurements.

- Calibrated Accuracy: Certified scales guarantee that businesses meet national standards for accuracy, crucial for trade and financial transactions.

7. Sustainability and Eco-Friendliness

- Environmentally Friendly: Solar-powered scales and energy-efficient models reduce carbon footprints, making them ideal for sustainable business operations.

- Waste Reduction: Some advanced scales come with features designed to minimize waste, such as auto shut-off or multi-use functionalities.

8. Improved Customer Experience

- Transparency: Accurate and efficient weighing processes provide customers with more trust in transactions.

- Faster Service: Businesses, especially those in retail, benefit from reduced wait times with the use of advanced scales, ensuring a better customer experience.

9. Remote Monitoring and Management

- Smart Technology: Scales connected to IoT or cloud-based systems enable remote monitoring, making it easier for businesses to manage operations across multiple locations in Uganda.

- Data Analytics: These technologies offer valuable insights into trends and performance, allowing businesses to adapt more effectively.

10. Maintenance and Support

- Long-Term Durability: Advanced scales come with warranties and comprehensive after-sales support, ensuring that businesses receive continuous maintenance and technical assistance.

- Service Networks: Suppliers like Eagle Weighing Systems offer nationwide service networks for fast repair and calibration services, ensuring uninterrupted operations.

Advanced weighing scales contribute significantly to the success of businesses and industries in Uganda by enhancing accuracy, efficiency, and sustainability. By adopting modern weighing technologies, businesses can streamline operations, improve customer satisfaction, and ensure compliance with national standards.

11. How to Optimize the Use of Weighing Scales in Your Business

To get the most out of your weighing scales, it’s essential to optimize their use. Whether you’re operating a small business or a large-scale industry in Uganda, proper utilization of weighing equipment can lead to improved efficiency, accuracy, and profitability. Below are some key steps to optimize your weighing scales:

1. Choose the Right Scale for Your Business Needs

- Identify Requirements: Different industries have different needs—be it weight capacity, precision, or portability. Choose a scale that matches your specific use case.

- Consult Experts: Work with suppliers like Eagle Weighing Systems to assess your business needs and recommend the best solution.

2. Regular Calibration and Maintenance

- Accurate Readings: Regular calibration ensures that your weighing scales provide accurate and reliable readings.

- Scheduled Maintenance: Timely servicing prevents breakdowns and ensures smooth operations.

- Compliance: Calibrated scales help businesses meet regulatory requirements in sectors like trade and manufacturing.

3. Proper Training and User Management

- Training Staff: Ensure that staff are properly trained to use the weighing scales efficiently, minimizing human errors.

- User-Friendly Interfaces: Opt for scales with intuitive interfaces and user-friendly designs that reduce operational complexity.

4. Implement Automated and Smart Solutions

- Integration with Technology: Use scales equipped with IoT or cloud capabilities for better data management and real-time monitoring.

- Automation: Automated scales improve efficiency by reducing manual intervention in weighing processes.

5. Optimize Scale Placement and Environment

- Location: Place scales on flat, stable surfaces to prevent measurement inaccuracies caused by uneven surfaces.

- Environment: Consider factors like temperature, humidity, and vibration that may affect readings, especially for precision scales used in laboratories or manufacturing.

6. Utilize Data Analytics for Decision-Making

- Analyze Data: Scales integrated with management software can generate valuable insights into inventory, production, and operational trends.

- Custom Reporting: Use these insights to adjust processes, reduce waste, and optimize workflows for better business outcomes.

7. Ensure Compliance and Regulatory Adherence

- Legal Standards: Keep scales calibrated and meet national regulations, such as those outlined in the Weights and Measures Act, to ensure legal compliance.

- Certification: Partner with certified suppliers for calibration services and scale certification to avoid penalties.

8. Enhance Sustainability Practices

- Energy-Efficient Options: Choose scales that use renewable energy, like solar-powered scales, to minimize environmental impact.

- Reduce Waste: Utilize scales with features that minimize overuse and reduce unnecessary waste.

9. Continuous Improvement and Upgrades

- Stay Current: Regularly assess and upgrade to newer models or technologies as weighing solutions evolve.

- Feedback Loop: Collect feedback from operations and users to identify areas for improvement.

10. Leverage Supplier Support and Service Networks

- After-Sales Support: Ensure your supplier offers comprehensive support for repairs, calibration, and spare parts availability.

- Nationwide Services: Working with suppliers who provide services across Uganda ensures that your scales remain in optimal condition no matter where your business operates.

Optimizing the use of weighing scales involves selecting the right solution, ensuring accurate operation, and integrating advanced features to meet the unique demands of your business. By adopting a comprehensive approach, businesses in Uganda can streamline operations, improve customer trust, and drive growth through efficient weighing solutions.

12. Common Challenges in Using Weighing Scales and How to Overcome Them

While weighing scales are essential tools in various industries, they come with their own set of challenges. Below are some of the common difficulties faced by businesses in Uganda when using weighing scales, along with solutions to overcome them.

1. Accuracy Issues and Calibration Problems

- Challenge: Inaccurate readings can lead to financial losses, regulatory issues, and reduced customer trust.

- Solution:

- Regular calibration by certified professionals.

- Use of advanced digital scales for higher precision.

- Work with suppliers like Eagle Weighing Systems for periodic maintenance and support.

2. Environmental Factors Affecting Performance

- Challenge: Factors such as temperature changes, humidity, dust, and vibration can impact scale accuracy.

- Solution:

- Use weatherproof and durable scales suitable for harsh environments.

- Ensure scales are placed on stable surfaces away from vibration sources.

- Opt for scales with automatic error correction features.

3. High Costs and Budget Constraints

- Challenge: Acquiring high-quality weighing scales can be expensive, especially for small businesses.

- Solution:

- Consider cost-effective yet durable options like portable or digital scales suited for specific needs.

- Seek financing or leasing options for expensive industrial-grade scales.

4. Maintenance and Downtime Issues

- Challenge: Frequent breakdowns or malfunctioning scales can disrupt business operations.

- Solution:

- Choose reliable suppliers with comprehensive service networks.

- Implement a maintenance schedule and stock spare parts for quicker repairs.

- Utilize remote monitoring for early detection of malfunctions.

5. Lack of Proper Training and User Mismanagement

- Challenge: Poor training leads to incorrect usage and data entry errors, reducing the efficiency of weighing processes.

- Solution:

- Provide thorough training for all operators using the scales.

- Opt for scales with user-friendly interfaces and automatic calibration options to minimize human error.

6. Limited Integration with Business Software

- Challenge: Older weighing systems may not integrate seamlessly with modern inventory or accounting software.

- Solution:

- Invest in scales that come with connectivity options such as Bluetooth or USB for easy data transfer.

- Work with suppliers to customize integrations tailored to specific business management systems.

7. Regulatory Compliance and Legal Issues

- Challenge: Non-compliance with national standards for accuracy and calibration may lead to fines and business suspension.

- Solution:

- Ensure all weighing scales are certified and adhere to Uganda’s Weights and Measures Act.

- Partner with trusted suppliers who offer legal compliance checks and calibration services.

8. Limited Mobility of Fixed Scales

- Challenge: Fixed scales are not suitable for businesses with frequent site changes, like agriculture or event management.

- Solution:

- Utilize portable or battery-operated scales for flexible and on-the-go weighing needs.

- Opt for wireless-enabled scales for remote use and data collection.

9. Security and Data Protection Concerns

- Challenge: Insecure data transmission from connected weighing systems may expose sensitive business information.

- Solution:

- Use encrypted communication protocols for data transfer.

- Implement access control features to secure who has access to sensitive information.

10. Market Competition and Innovation Pressure

- Challenge: Keeping up with technological advancements and offering innovative solutions can be challenging for small or mid-sized businesses.

- Solution:

- Stay updated with the latest weighing scale technologies through industry events, workshops, and supplier consultations.

- Collaborate with suppliers like Eagle Weighing Systems to explore emerging trends and solutions.

While weighing scales provide invaluable support for businesses, addressing challenges such as accuracy, maintenance, cost, and technology integration is essential for maximizing their potential. By leveraging advanced solutions and professional services, businesses in Uganda can ensure smooth operations and sustained growth.

13. Choosing the Right Weighing Scales for Your Business in Uganda

Selecting the appropriate weighing scales is crucial for ensuring optimal performance and efficiency in various business operations. In Uganda, businesses have diverse needs, from retail and agriculture to manufacturing and logistics. Below is a guide to help you choose the right weighing scales for your specific business requirements.

1. Types of Weighing Scales

- Digital Scales: Ideal for precision, offering high accuracy in a variety of industries. Perfect for businesses requiring detailed weight measurements, such as jewelry, pharmaceuticals, and agriculture.

- Analog Scales: Suitable for basic weighing tasks where high precision isn’t critical, such as in factories or for bulk weighing.

- Platform Scales: Used for weighing large items like sacks of crops or machinery parts. Common in warehouses, agriculture, and manufacturing industries.

- Portable Scales: Versatile for on-the-go measurements. Useful for market vendors, farmers, and businesses requiring flexibility.

2. Considerations for Specific Industries

- Agriculture: Scales like livestock scales or large platform scales are used for weighing produce, grains, and animals. These scales should handle high capacities and harsh environmental conditions.

- Retail: Precision digital scales with connectivity features are ideal for precise pricing in supermarkets, weighing small consumer goods.

- Manufacturing: Industrial scales are essential for heavy-duty weighing, supporting processes like assembly, packaging, and quality control.

3. Capacity Requirements

- High Capacity: Needed for large quantities such as bulk produce, construction materials, or industrial goods.

- Low Capacity: Suitable for smaller, detailed measurements such as chemicals, spices, or jewelry.

4. Features to Look For

- Accuracy: Ensure scales provide accurate readings for your specific needs.

- Durability: Scales should withstand environmental factors like dust, moisture, and vibrations.

- Connectivity: Modern scales with Bluetooth, USB, or cloud integration offer seamless data management.

- Power Options: Solar-powered or battery-operated scales provide flexibility in remote or off-grid areas.

5. Budget and Cost Considerations

- Initial Investment: Consider the cost of purchase, installation, and any additional software or support needed.

- Long-Term Savings: High-quality scales may be expensive upfront but save costs over time by reducing errors and improving efficiency.

6. Regulatory and Legal Compliance

- Certification: Ensure your scales meet Uganda’s national standards (e.g., Weights and Measures Act).

- Maintenance: Partner with suppliers offering certified calibration services to maintain accuracy and compliance.

7. Supplier Selection and Support

- After-Sales Service: Reliable support, including maintenance, repair, and spare parts supply, is crucial.

- Local Presence: Working with suppliers with a strong presence in Uganda ensures quick and effective service.

8. Sustainability and Eco-Friendliness

- Energy-Efficient Options: Solar-powered or battery-operated scales are eco-friendly and cost-effective.

- Waste Reduction: Advanced models with features like auto-off can minimize unnecessary energy consumption.

Choosing the right weighing scales involves assessing factors such as capacity, accuracy, features, and industry needs. By understanding these elements, businesses in Uganda can select solutions that enhance operational efficiency and contribute to long-term growth.

14. Maintaining and Extending the Lifespan of Weighing Scales

Regular maintenance and proper handling are essential to ensuring the longevity and optimal performance of your weighing scales. Below are key practices for maintaining your scales and extending their lifespan, particularly useful for businesses in Uganda.

1. Routine Calibration and Accuracy Checks

- Why It’s Important: Calibration ensures that scales provide precise and reliable readings, which is crucial for compliance with regulatory standards and maintaining customer trust.

- Best Practices:

- Conduct calibration regularly using certified professionals.

- Use certified test weights or standards for accuracy verification.

- Automate calibration where possible for frequent or heavy usage scales.

2. Cleaning and Preventive Maintenance

- Why It’s Important: Preventive care minimizes breakdowns, improves efficiency, and ensures the longevity of scales.

- Best Practices:

- Clean scales regularly to prevent dust, dirt, and debris from affecting performance.

- Check for wear and tear on components such as sensors, load cells, and display units.

- Lubricate moving parts and ensure all seals and covers are intact.

3. Proper Scale Placement and Environment Management

- Why It’s Important: Proper placement and environmental control reduce errors and prevent premature wear.

- Best Practices:

- Place scales on stable, level surfaces to avoid inaccuracies.

- Minimize exposure to extreme temperatures, vibrations, and moisture.

- Use protective covers for outdoor or high-risk environments.

4. Training and Education

- Why It’s Important: Proper training helps operators handle scales efficiently, reducing errors and ensuring the best outcomes.

- Best Practices:

- Train employees on the proper use of weighing scales.

- Implement a structured user management system to control who operates and handles the scales.

5. Regular Inspections and Maintenance Checks

- Why It’s Important: Scheduled inspections ensure early detection of issues and prevent major breakdowns.

- Best Practices:

- Schedule periodic inspections with suppliers like Eagle Weighing Systems.

- Monitor performance metrics to assess wear and operational efficiency.

6. Data Management and Backup

- Why It’s Important: Maintaining accurate records of scale usage and performance can help in troubleshooting and optimizing operations.

- Best Practices:

- Use software solutions that provide real-time data tracking and management.

- Regularly back up important data for compliance and historical analysis.

7. Upgrade and Replacement Strategies

- Why It’s Important: Outdated or worn-out scales can compromise operational accuracy and efficiency.

- Best Practices:

- Plan for the replacement of older models with modern, more efficient weighing solutions.

- Consider supplier programs for trade-in or upgrade discounts for older scales.

8. Compliance and Certification

- Why It’s Important: Maintaining compliance with national standards for weighing equipment ensures legal and operational efficiency.

- Best Practices:

- Regularly update certification for scales under the Weights and Measures Act.

- Ensure scales are always in calibration and pass annual inspections.

9. Sustainable Practices

- Why It’s Important: Implementing eco-friendly solutions ensures long-term sustainability and reduces costs.

- Best Practices:

- Choose energy-efficient, eco-friendly scales to minimize environmental impact.

- Recycle or properly dispose of old scales and components.

Effective maintenance and care for weighing scales not only ensure their accuracy and performance but also extend their useful life. By following these best practices, businesses in Uganda can maintain efficient weighing systems that meet operational and regulatory needs for years to come.

15. Future Trends in Weighing Scales for Businesses in Uganda

The weighing scale industry is continuously evolving, driven by technological advancements and the growing demand for more efficient and versatile solutions. Below are some of the key future trends that businesses in Uganda can expect to see in weighing scales.

1. Smart and IoT-Enabled Weighing Scales

- Trend: Smart scales integrated with IoT (Internet of Things) are becoming more common, allowing seamless data collection, real-time monitoring, and remote management.

- Impact:

- Businesses can access data from multiple locations without physical interference.

- Enhanced inventory management, predictive maintenance, and efficiency optimization.

- Suppliers like Eagle Weighing Systems are incorporating IoT features for better business insights.

2. Increased Use of Cloud Computing for Data Management

- Trend: Cloud-based weighing scales are becoming more prevalent, facilitating data sharing, analysis, and secure backups.

- Impact:

- Businesses can easily access and manage scale data from anywhere.

- Integration with ERP systems, making supply chain and business processes smoother.

- Businesses in Uganda can benefit from scalability without investing heavily in on-premises storage solutions.

3. Enhanced Accuracy through Advanced Sensor Technology

- Trend: Developments in sensor technology are enabling scales to provide higher accuracy, especially in industries like healthcare, agriculture, and manufacturing.

- Impact:

- Improved reliability for critical applications where precision is essential.

- Reduction in human error, leading to more accurate measurements for pricing, logistics, and compliance.

- Suppliers in Uganda are adopting these advancements to offer cutting-edge solutions.

4. Integration with Mobile and Wearable Devices

- Trend: Weighing scales that connect to smartphones, tablets, or even wearable devices are becoming increasingly popular.

- Impact:

- Users can access scale data on-the-go, allowing flexibility in operations.

- Real-time data collection supports faster decision-making and better resource allocation.

- Mobile-friendly solutions enable market vendors and small businesses to streamline weighing processes.

5. Enhanced Sustainability and Energy Efficiency

- Trend: Eco-friendly and energy-efficient weighing scales are being designed to meet environmental standards and reduce operating costs.

- Impact:

- Solar-powered and battery-operated scales are ideal for remote areas without access to consistent electricity.

- Businesses can adopt green practices that align with Uganda’s sustainability goals, including zero-waste initiatives.

- Suppliers are providing scales that balance performance with eco-friendliness.

6. Customizable Solutions for Industry-Specific Needs

- Trend: Tailored weighing scales for specific industries, such as agriculture, food processing, logistics, and healthcare, are gaining popularity.

- Impact:

- Scales designed to handle unique challenges in each sector provide better efficiency and adaptability.

- Businesses can choose models with specific features like waterproofing, heavy-duty capacity, or sanitary design to meet their specific operational needs.

7. Real-Time Reporting and Analytics

- Trend: Scales equipped with advanced analytics tools allow businesses to monitor performance, track trends, and make informed decisions instantly.

- Impact:

- Managers can optimize workflows based on historical and real-time data.

- Faster issue resolution with insights into scale performance helps avoid costly downtime.

8. Advanced Security and Data Protection

- Trend: With the rise in data breaches and cyber threats, security features such as encryption and access control are becoming essential for weighing scales.

- Impact:

- Ensures sensitive business data is protected, especially for companies handling customer information or regulated products.

- Suppliers in Uganda are offering secure, robust weighing systems to protect business operations.

The future of weighing scales in Uganda is marked by technological innovation, tailored solutions, and sustainability. By adopting advanced technologies, businesses can streamline their operations, enhance efficiency, and ensure compliance with evolving industry standards.