What Is a Moisture Meter Used For? – Key Functions in Uganda, A moisture meter is an essential device used to measure the moisture content in various materials. From agricultural produce to construction materials, knowing the moisture levels is critical for quality assurance, safety, and efficiency. In Uganda, moisture meters play a pivotal role in diverse industries, ensuring optimal performance and preventing losses.

Key Uses of a Moisture Meter

1. Agriculture and Farming

- Purpose: To determine the moisture content in grains, seeds, soil, and other crops.

- Importance:

- Prevents post-harvest losses by ensuring grains are dry enough for storage.

- Guides irrigation by assessing soil moisture levels, enhancing crop yields.

- Example: A maize farmer in Uganda uses a moisture meter to ensure harvested maize has a moisture content below 13% for safe storage.

2. Construction and Building

- Purpose: To measure the moisture levels in building materials such as wood, concrete, and drywall.

- Importance:

- Ensures materials meet required moisture standards to prevent structural issues.

- Identifies potential dampness or water intrusion in existing structures.

- Example: Before laying a concrete floor, contractors in Uganda use a moisture meter to verify the slab is dry enough to avoid cracking.

3. Woodworking and Timber Industry

- Purpose: To assess the moisture content in wood before processing or installation.

- Importance:

- Prevents warping, cracking, and shrinkage in finished products.

- Ensures wood is seasoned to the correct moisture level for furniture or construction.

- Example: Furniture makers in Uganda use moisture meters to confirm wood has a moisture content of 6–8% before crafting.

4. Food Processing and Storage

- Purpose: To maintain optimal moisture levels in food products such as coffee, tea, or dried fruits.

- Importance:

- Ensures food safety by preventing mold growth and spoilage.

- Guarantees quality standards are met for export or local markets.

- Example: Coffee processors in Uganda rely on moisture meters to confirm beans are dried to 10–12% moisture content.

5. Paper and Textile Industry

- Purpose: To measure moisture levels in paper, cardboard, fabrics, and other materials.

- Importance:

- Maintains product quality by preventing damage caused by excess moisture.

- Ensures consistency in manufacturing processes.

- Example: Printers in Uganda use moisture meters to prevent paper from curling or jamming due to excess humidity.

6. Environmental Monitoring

- Purpose: To monitor moisture in soils, air, or other environments.

- Importance:

- Helps in ecological research and environmental conservation efforts.

- Aids in planning irrigation and water management projects.

- Example: Researchers in Uganda use soil moisture meters to study wetland dynamics.

Types of Moisture Meters

- Pin-Type Moisture Meters

- How They Work: Use electrodes that penetrate the material to measure moisture levels.

- Best For: Wood, drywall, and other solid materials.

- Pinless Moisture Meters

- How They Work: Use electromagnetic waves to measure moisture without penetrating the material.

- Best For: Sensitive surfaces like finished wood or textiles.

- Soil Moisture Meters

- How They Work: Use probes inserted into the soil to measure moisture content.

- Best For: Agricultural and horticultural applications.

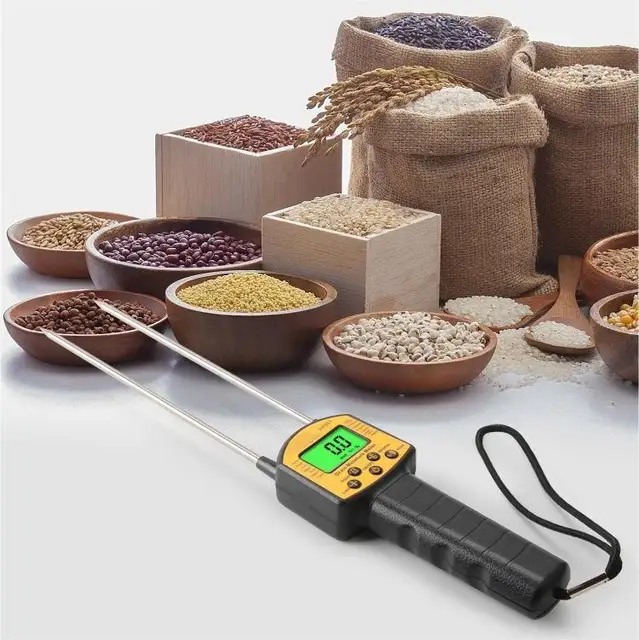

- Grain Moisture Meters

- How They Work: Specifically designed to test moisture content in grains like maize, rice, and beans.

- Best For: Farmers and grain storage facilities.

Benefits of Using a Moisture Meter

- Prevents Losses

- Accurate moisture readings help avoid spoilage, cracking, or decay in materials.

- Improves Product Quality

- Ensures materials like crops, wood, and concrete meet quality standards.

- Enhances Efficiency

- Guides decision-making in farming, construction, and manufacturing.

- Saves Costs

- Detects potential issues early, reducing repair or replacement costs.

- Supports Compliance

- Meets industry regulations for export, building safety, and food standards.

How to Use a Moisture Meter

- Select the Right Type

- Choose a moisture meter suitable for your material (e.g., soil, grain, or wood).

- Prepare the Material

- Clean the surface to remove dirt or debris that could affect readings.

- Take the Measurement

- For pin-type meters, insert the pins into the material.

- For pinless meters, place the device flat on the surface.

- Interpret the Results

- Compare the readings with recommended moisture levels for your application.

- Calibrate Regularly

- Ensure accuracy by calibrating the device as per the manufacturer’s instructions or with professional services.

Why Choose Eagle Weighing Systems for Moisture Meters in Uganda?

Eagle Weighing Systems is the go-to provider of high-quality moisture meters and weighing equipment in Uganda. Here’s why:

- Wide Selection: From grain to soil moisture meters, they offer devices for every need.

- Expert Guidance: Professional advice to help you select the best meter for your application.

- Affordable Pricing: Competitive rates in Ugandan Shillings (UGX).

- After-Sales Services: Calibration, maintenance, and repair services to ensure long-term reliability.

- Accessible Platforms: Explore their offerings on the official website and connect via Facebook, Twitter, and YouTube.

What Is a Moisture Meter Used For? – Key Functions in Uganda

Moisture meters are invaluable tools for ensuring quality, efficiency, and compliance in various industries across Uganda. From farming to construction, these devices empower users to make informed decisions, save costs, and improve productivity.

For reliable moisture meters and expert support, trust Eagle Weighing Systems. Visit them today for all your moisture measurement needs