Description

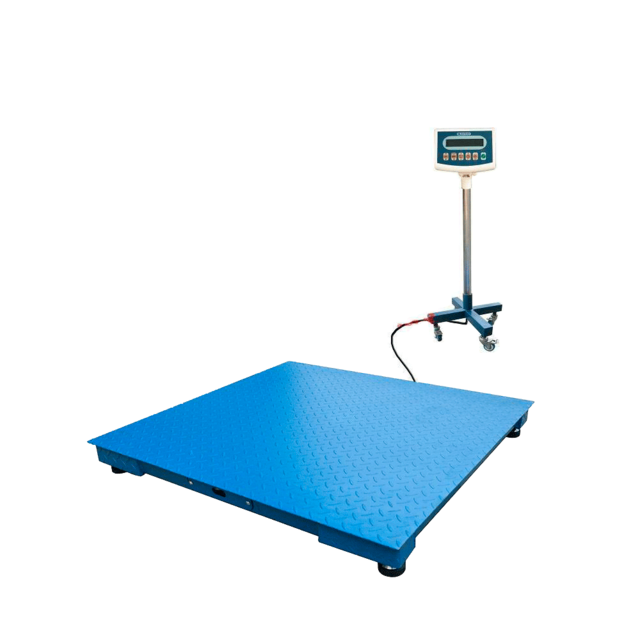

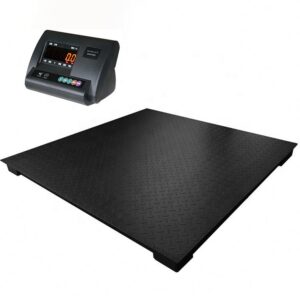

Manufacturing Industries Floor Scale. Electric warehouse weighing scales are essential tools for modern warehouses, offering precision, efficiency, and convenience in weighing operations. These scales are designed to handle various loads, from small packages to large pallets, making them integral to inventory management, shipping, and receiving processes. This comprehensive meta description explores the features, benefits, applications, and considerations of electric warehouse weighing scales, with a focus on their usage in warehouse environments.

Features of Electric Warehouse Weighing Scales

High Precision and Capacity:

- Accurate Measurements: Equipped with high-precision sensors, these scales provide accurate weight readings, essential for inventory accuracy and shipping calculations.

- Wide Range of Capacities: Available in various capacities, from a few kilograms to several tons, catering to different warehouse needs. Manufacturing Industries Floor Scale

Versatile Platform Sizes and Designs:

- Different Platform Sizes: Available in multiple platform sizes to accommodate different types of loads, from small packages to large pallets.

- Specialized Designs: Includes pallet scales, floor scales, and bench scales, each designed for specific warehouse applications.

Compliance and Record Keeping:

- Regulatory Compliance: Helps ensure compliance with industry standards and regulations for weight measurements.

- Accurate Documentation: Facilitates accurate record-keeping for audits, inventory management, and quality control.

Applications of Electric Warehouse Weighing Scales

Quality Control:

- Product Verification: Verifies the weight of products during quality control checks, ensuring consistency and adherence to specifications.

- Batch Weighing: Supports batch weighing for quality control of bulk items, ensuring uniformity and compliance with standards.

Key Considerations When Choosing Electric Warehouse Weighing Scales

Capacity and Precision:

- Weight Range: Select a scale with an appropriate weight capacity for your specific needs, considering the heaviest items you will measure.

- Accuracy Requirements: Ensure the scale provides the necessary level of precision for your warehouse applications.

Durability and Maintenance:

- Material Quality: Opt for scales made from robust, durable materials that can withstand heavy use and harsh environments.

- Maintenance Needs: Consider the ease of maintenance and availability of spare parts to ensure long-term reliability.

Conclusion

Electric warehouse weighing scales are indispensable tools for modern warehouses, offering the necessary precision, efficiency, and convenience for various weighing operations. With features such as high precision, robust construction, advanced connectivity, and user-friendly interfaces, these scales enhance operational efficiency, accuracy, and cost savings. Whether for inventory management, shipping and receiving, order picking, packing, or quality control, investing in high-quality electric warehouse weighing scales ensures improved productivity, compliance with regulations, and long-term reliability. By carefully considering factors such as capacity, durability, ease of use, and connectivity, businesses can select the best scales to meet their specific needs and achieve optimal performance in their warehouse operations.

Reviews

There are no reviews yet.