Description

Cost of a Weighbridge in Uganda

The cost of a weighbridge in Uganda varies depending on factors such as the type, size, capacity, and additional features. Below is an estimated price range for different types of weighbridges in Uganda:

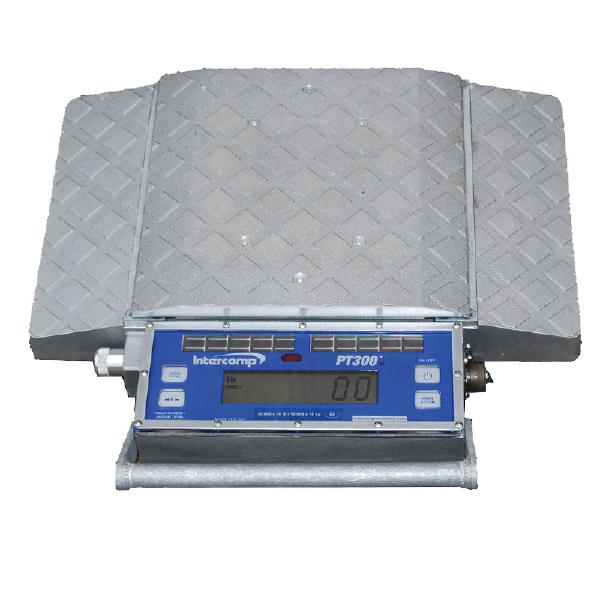

1. Portable Weighbridges

Portable weighbridges are easy to install and can be moved from one location to another. They are commonly used in temporary or semi-permanent setups such as construction sites and agricultural fields.

- Price Range: UGX 50,000,000 to UGX 150,000,000

- Features: Mobility, ease of setup, lower capacity compared to fixed weighbridges.

2. Permanent (Fixed) Weighbridges

These are installed in a permanent location and are often used for long-term applications in industries like mining, logistics, and large-scale agriculture.

- Price Range: UGX 100,000,000 to UGX 350,000,000

- Features: Higher capacity, long-term durability, requires substantial installation.

3. Axle Weighbridges

Axle weighbridges measure the weight of each axle of a vehicle separately and are ideal for road transport companies and enforcement of vehicle weight regulations.

- Price Range: UGX 80,000,000 to UGX 200,000,000

- Features: Suitable for heavy-duty vehicles, helps in ensuring axle load compliance.

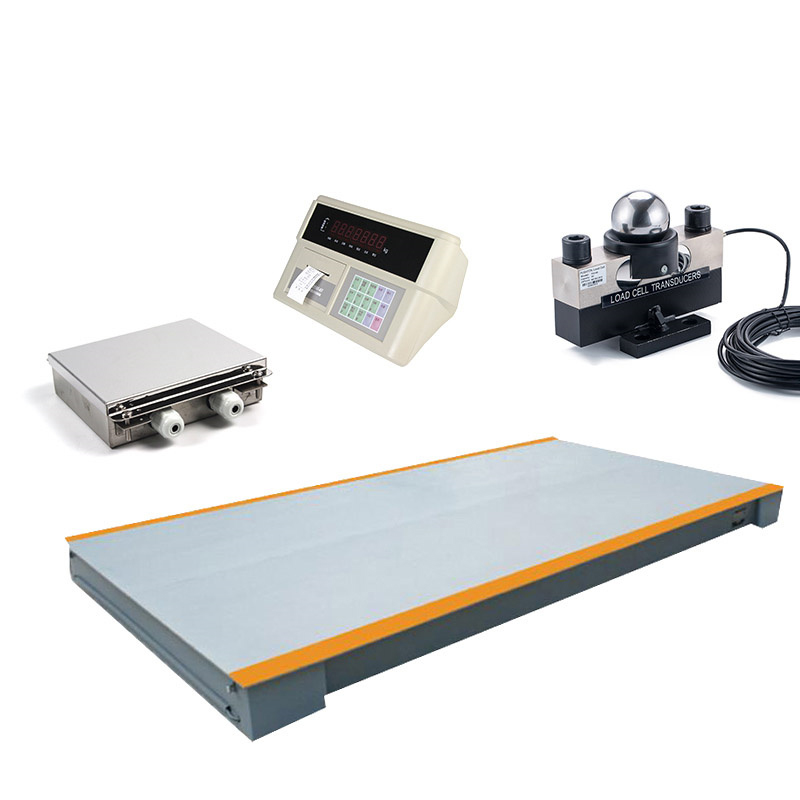

4. Digital Weighbridges

These weighbridges come with advanced features such as digital readouts, data storage, and software integration for enhanced accuracy and efficiency in operations.

- Price Range: UGX 120,000,000 to UGX 400,000,000

- Features: Digital displays, automation, data logging, and remote monitoring options.

5. Weigh-in-Motion Weighbridges

These weighbridges allow vehicles to be weighed while in motion, making them useful for high-traffic areas like toll plazas or checkpoints.

- Price Range: UGX 200,000,000 to UGX 500,000,000

- Features: Fast and efficient weighing, suitable for heavy traffic environments, higher price due to technology.

Factors Affecting Weighbridge Costs

- Capacity: Weighbridges with higher capacities (e.g., up to 100 tons) are generally more expensive.

- Technology: Advanced systems with features such as digital displays, automation, and data management systems tend to cost more.

- Installation Costs: Fixed weighbridges require significant groundwork and construction for installation, adding to the total cost.

- Brand and Quality: Well-known brands with a reputation for durability and accuracy often come at a premium.

- Customization: Custom-designed weighbridges for specific industries or needs (e.g., mining or logistics) may be more expensive.

Additional Costs

- Installation and Foundation: The installation cost for permanent weighbridges can add significant expenses, depending on the complexity of the foundation required.

- Calibration and Maintenance: Regular calibration is essential to maintain the accuracy of the weighbridge, which incurs ongoing costs.

Reviews

There are no reviews yet.